How the Railroad Industry Invented, Then Immediately Discarded, the Barcode

Credit to Author: Ernie Smith| Date: Tue, 24 Oct 2017 13:00:00 +0000

A version of this post originally appeared on Tedium , a twice-weekly newsletter that hunts for the end of the long tail.

Trying to codify and organize things is really hard. Case in point: When Amazon tried to launch a cashier-free grocery store concept late last year, the company saw a lot of problems crop up when too many customers used the store at the same time.

On a macro level, the railroad industry once faced similar problems with automatically tracking things—a problem it started working on 60 years ago, without the benefits of modern innovation.

In fact, the industry actually created a lot of that innovation. To put it another way: Before the barcode hit the grocery store, it hit rail cars, and not in a way you might expect.

Here’s the story of the KarTrak, the unsuccessful idea that laid the tracks for a far-more-successful idea.

“Barcode still has a lot of life in it. It’s still the backbone of retailing and manufacturing, and has other uses. Look at FedEx. The barcode allows you the follow the path of a package until it is delivered. It also has military applications.”

— David J. Collins, a key innovator in the history of the barcode, discussing his innovation in a 2011 article with the Newport, Rhode Island Daily News. Before it took its most common form, Collins had created a variation of it that was mainly used in industrial applications—one that looks nothing like today’s barcode.

The annoying problem that KarTrak was trying to solve

The US rail industry, due to its large size and the sheer amount of stuff being delivered on its tracks at all times, had a fundamental challenge: Tracking where an individual car was going was really hard, and cars would often get lost. There was a code-based system in place for tracking these cars, but it is complex and incomprehensible to the average person.

This is a place where technology could help, clearly. But the needs of the railroad system meant that technology providers had a particularly unique and frustrating challenge in front of them.

Here was the hard part of this riddle: The industry needed a solution that worked while the train was moving, perhaps as fast as 60 miles per hour. No delays allowed. No stopping, either.

And because trains travel through all sorts of elements—rain, snow, wind, light, dark—that tracking has to work in basically any setting. And because it had to go on so many train cars, it had to be cheap—no more than, say, a dollar per device.

Railroads had already been trying to solve this problem since the late 19th century, but by the late 1950s, the technology was starting to catch up to the need—and vendors were lining up with ideas.

A search of US patents during this era highlights numerous solutions that range from novel to game-changing. Among them: a magnetic coding system that works akin to the head of a tape deck, a solution relying on a motion picture camera, and a system relying on microwave identification. Basically, if it was a hot new technology, the rail industry was willing to consider it for this specific purpose.

David J. Collins, then an employee for the General Telephone and Electronics (GTE) subsidiary Sylvania, was in a good position to solve the problem, because he was already aware of it. A MIT graduate, Collins spent his undergraduate years working on the Pennsylvania Railroad, where he saw the challenges of tracking trains first-hand.

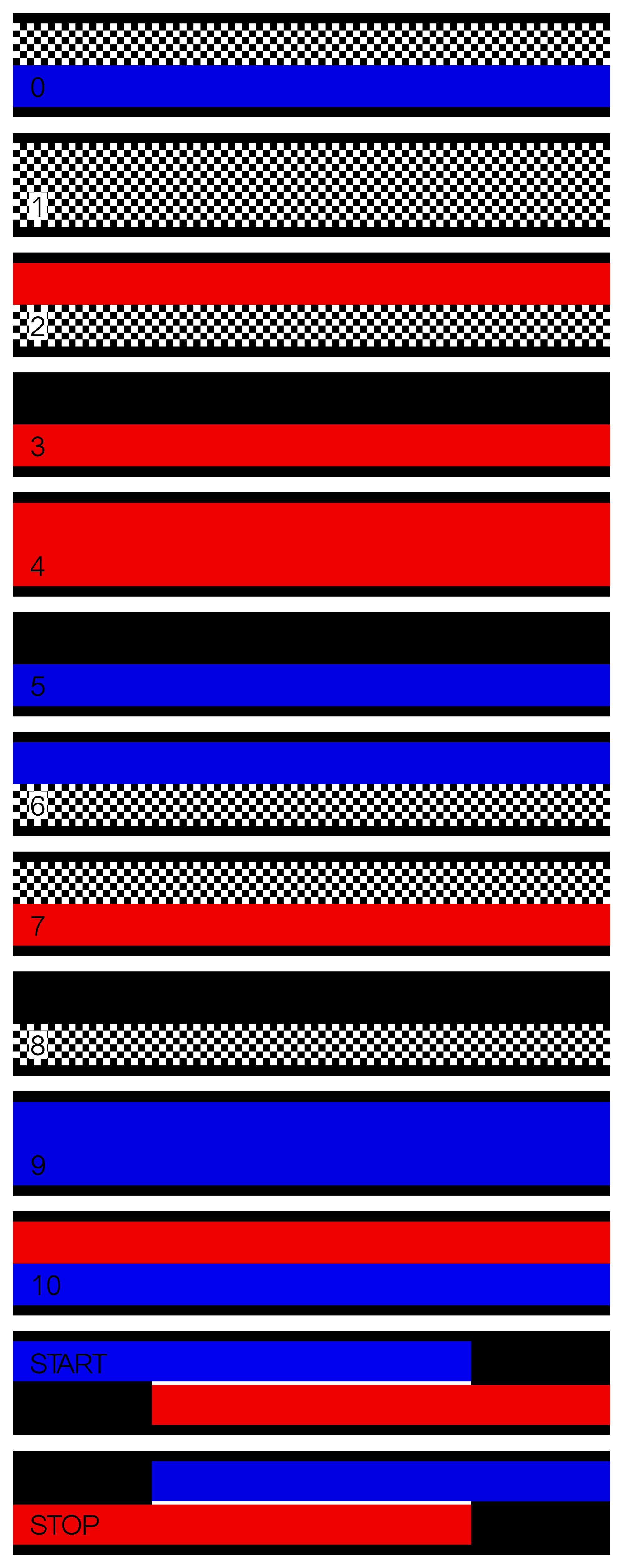

It was useful knowledge for Sylvania’s Applied Research Lab, which was looking for a project that would put the company’s mainframe computers to good use. The solution Collins and his colleague Chris Kapsambelis came up with didn’t really do that, but it was fairly innovative in its own right. Using a series of reflective color bars as a layer of abstraction from the complicated codes, the codes were then optically scanned using helium-neon lasers that were intended to pick up the details of the codes, no matter the weather.

In a 2011 newsletter for his current company, A2B Tracking Solutions, Collins explained the experimentation that led to the creation of KarTrak:

The management of this division planned to introduce a large-scale (IBM 709-size) commercial computer developed as a spin-off of an Army contract to deliver a “hardened” field computer. Since there was no known market niche for another IBM-sized computer, I suggested our new computer be pared with a system of scanners to read and report on the lost railroad car problem described in the 1889 patent. As an undergrad engineering student, I had worked several summers for the Pennsylvania Railroad, and knew that “lost” railcars were a problem still unsolved. Sylvania management tossed me the ball to manage this scanner development.

Sylvania’s Applied Research Lab staff of 150 advanced degree scientists and engineers represented the pool of resources I could tap for this project. Initially, all practical paths for active and passive “pattern” recognition were explored within the lab, but by the end of 1960, light transmission was selected as the medium for label/scanner development. From this time until the end of the project, 3M Company teamed with Sylvania to coordinate on label technology.

The technology was first installed in test forms on the Boston and Maine Railroad in 1961 and subsequently improved. But uptake was somewhat slow—while 50,000 cars were labeled with the technology in the mid-60s, that was only a small portion of the overall train system. The hard part of selling an idea that really needed buy-in from the entire railroad industry to be successful is selling it, and Sylvania started with a full-page ad in the Wall Street Journal promising “to save American railroad over three billion dollars.”

A bold claim, sure. But it eventually caught on when, in 1967, the Association of American Railroads put KarTrak and 10 other competing technologies in competition with one another as the industry standard. Sylvania had a few factors in its favor: It spent years building up a base of captive railroads, plus—unlike competing technologies like microwaves—it was generally ready to go, rather than a few years off.

KarTrak won, with its technology eventually becoming known in the industry as automatic car identification (ACI). And soon, those reflective codes were on every single freight train car in the entire country. But, as it turned out, the codes weren’t enough on their own.

Why KarTrak eventually petered out, and why that didn’t matter in the end

The rail industry may have seemingly embraced KarTrak wholeheartedly, spending $150 million on its implementation between 1967 and 1977, according to the St. Louis Post Dispatch. At its peak, 95 percent of rail cars had a KarTrak code on the side.

But the company that owned the technology had a vision that went far beyond railroad tracks. A GTE ad in a 1971 edition of Fortune laid out that vision for KarTrak:

Soon every railroad car will have an identifying label. It won’t be long before railroad users everywhere start feeling the benefits of better service that come from better car control. But that’s only the beginning. In other versions automatic identification systems are already being used in subways, are being tested by several trucking companies and are being developed for use as total transportation, production line, materials handling and other information and control systems.

And there was some evidence of this experimentation taking place—for example, this 1967 article citing the potential use of KarTrak as a way to automatically track cars going through the toll booth on the New Jersey Turnpike.

But there was just one problem with the claim: It was pure lip service. David J. Collins, the guy who masterminded the whole idea of automatic car identification, had already moved on, failing to sell his employer on improvements to the concept.

Soon, Collins had launched his own company, Computer Identics, which took steps to further improve upon the technology—around the time that the idea was being translated to grocery stores.

The telephone-rooted GTE, meanwhile, realized it wasn’t actually interested in the rail business—it sold its investment in KarTrak to Servo in 1972, a move that was part of a broader trend at the time of large companies selling niche businesses.

And while Servo continued to improve KarTrak, creating a self-cleaning variation on the labels that it patented in 1975, the technology was not long for this world.

A federal appeals court ruling in a case between Collins’ Computer Identics and Southern Pacific Company, which the railroad won, lays out a somewhat depressing case of corporate inertia. Here’s the gist: While the Association of American Railroads required every rail car to have an ACI tag visible somewhere, there was nothing forcing individual railroad companies to buy the necessary technology to make those tags useful. And during this time—as proven by the existence of Amtrak—the railroad industry wasn’t doing so hot, so there wasn’t a lot of encouragement to buy new equipment at the time, which was bad for Collins’ company.

The result was that, while the market could support more than 10,000 scanners, just 400 were sold to railroads between 1967 and 1975.

There were more fundamental problems at play, too. A 1999 Trains article noted that the codes, despite being sold as able to avoid the elements, would get covered in snow and mud and would fail to read. And while KarTrak was initially the product of an attempt to sell mainframe computers, it was surprisingly not very computerized.

“A larger problem was that ACI was not integrated with any computer systems—it only gave a printout for an individual ACI scanner,” author Sean Graham-White wrote. “As trains passed, ACI scanner printers spewed forth, but over time the accumulated paperwork was ignored.”

AAR eventually gave up on the standard in 1977, with little to show for it beyond decals that show up on era-appropriate model trains.

In the end, though, the loss of KarTrak as a technology failed to dull the innovation created by Collins. In fact, around the time that the train industry was starting to move away from KarTrak, Collins’ company was helping create an application that was functionally very similar to the railroad industry’s need.

In 1977, the New York City Marathon was struggling with growth, because manual trackers (also known as humans) were unable to easily keep an eye on who was going through the finish line. Enter the barcode. Collins had devised a barcode-based system that would allow runners to know their running time and place within 15 minutes of crossing the finish line.

(Per Popular Mechanics, Collins himself ran in the race and scored a time of 3:35.)

The results were clear: Even if the railroads couldn’t figure out how to make barcodes work, there were plenty of other industries that would.

Or, to put it another way: KarTrak became a footnote in the history of the barcode, while Collins literally wrote the book on the subject.

In the end, it turned out that the real solution to the railroad industry’s problem wasn’t barcodes, but radio-frequency identification, better known as RFID. Invented in the 1940s, it wasn’t ready for prime time in the days of KarTrak. But it eventually found its place in the market.

In some ways, the technology works very similarly to the reflective barcodes—in that an object is placed on the side of a railway car, and it’s tracked while it’s in transit.

The difference, of course, is accuracy. When Burlington Northern Railroad did a trial of the technology in 1988, it found the accuracy rate of RFID was 99.9 percent, which was way higher than specialized barcodes could ever hope for. And because visuals weren’t involved, it meant that the issues that made barcodes a bad solution for fast-moving trains were no longer an issue.

While the railroad system didn’t invent RFID, it popularized the technology—and it was in wide use by freight trains by the early 90s. It’s still pretty common today, in fact.

RFID, like the barcode system, is now basically everywhere. For example, the airline industry is currently working to install RFID trackers on basically every part of its baggage process, in a way not unlike the rail industry decades prior.

So anyway, I wasn’t completely forthcoming: The rail industry actually popularized two scanning technologies. They only stuck with one.