Bricklaying Robots And Exoskeletons Are the Future of the Construction Industry

Credit to Author: David Silverberg| Date: Mon, 21 Aug 2017 17:11:32 +0000

One of the most staid and digitally conservative industries is on the verge of a robotic makeover.

The global construction space isn’t known for ushering new tech into their workforce, but a painful labour shortage, calls for increased worker safety and more low-cost housing, and the need to catch up to other tech-savvy sectors is giving upstarts in robotics and exoskeletons their big moment.

Even so, there’s concern that automation could put some workers out of a job. According to a report from the National Bureau of Economic Research, each additional robot in the American economy lowers employment by 5.6 workers, and every robot that is added to the workforce per 1,000 human workers causes wages to drop by as much as 0.25 to 0.5 percent.

The construction industry isn’t immune to this phenomenon, but robots and humans may increasingly work hand-in-hand in industrial sectors, according to Brian Turmail, senior executive director of public affairs at the Associated General Contractors of America. This is especially true when the construction industry en masse uses exoskeleton vests, which aim to assist workers with heavy loads and thus reduce their risk of injury.

But some robots may do the majority of back-breaking work for construction workers that repeat the same routine for hours.

The Hadrian X is a bricklaying robot courtesy Australia’s Fastbrick Robotics, which uses its 30-metre metal arm to lay bricks at a rate of 1,000 bricks per hour, compared to a human worker’s average of 1,000 a day. Due for release in late 2017, Hadrian X can read a 3D CAD model of the house and then it follows those instructions precisely, working day and night.

Video: Fastbrick Robotics/YouTube

“[Automation] is a need now, not a want,” Mike Pivac, president of Fastbrick Robotics, told reporters in 2016. “We have to do this. If we’re going to satisfy the global need for low-cost housing over the next 30 years, as we add another 3 billion people to the planet, we see solutions like this as being very, very important.”

New York-based Construction Robotics has also developed its take on a bricklaying robot. SAM can lay 3,000 bricks a day, and the company said it’s about time this industry got a whiff of the change almost every other market has been seeing.

“The efficiency in construction sites has been very stagnant or declined in the last 20, 30 years whereas manufacturing efficiency has increased significantly and a lot of that is due to robotics and technologies,” Scott Peters, President of Construction Robotics, told VICE News.

“The availability of robotics in the industry is pretty thin,” according to Dan Kara, president of the robotics research division at ABI Research. “Sure, we’ve had automation on assembly lines since the ’70s, but that’s doing a fixed task over and over. In construction, you’re not making 1 million refrigerators but moving around a lot, climbing on scaffolds, laying down palettes, and that’s a challenge.”

Amid fears of widespread automation, there are signs the industry might need non-human help. In June 2017, 154,000 open jobs were available in US construction, compared to 84,000 in May 2012 and a low of 41,000 in May 2009, according to the US Bureau of Labor Statistics.

Robots don’t “replace the need for workers,” according to Brian Turmail, senior executive director of public affairs at the Associated General Contractors of America, who answered questions over email. “They change the skill set, mix, and possibly location (e.g., construction site or factory) of workers who are needed.”

Without such technological advances, Turmail added, projects may fall short of the workers needed, which would risk delay home construction and drive up costs.

The mainstream construction players are taking notice: In July, construction equipment giant Caterpillar announced it will partner with Fastbrick by investing $2 million in the company and aiming to develop the framework for bringing the Hardian X to Caterpillar customers.

Robotics are also playing a role when it comes to the work actual humans are doing in the construction industry. Look at exoskeletons, which are next-gen arm slings or vests designed to offload the weight of heavy repetitive industrial work. Picture them as robotic armour for construction workers tasked with doing the same thing over and over, like tiling or heavy-duty drilling.

Some construction workers may never suffer a crippling injury, but their bodies can wear down after years of back-buckling work. Some firms, like California-based Ekso Bionics, are aiming to help the aging workforce. In September it will debut its new EksoVest in September, which can support loads of between five and 15lbs per arm.

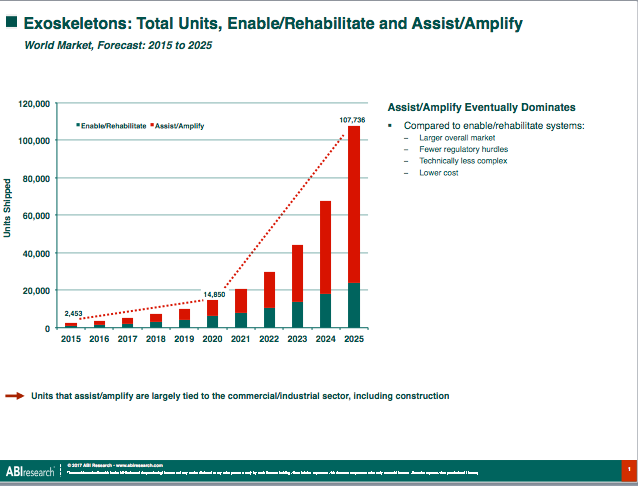

The robotic exoskeleton market is poised to grow to $1.9 billion in 2025, compared to $97 million in 2016, says ABI Research’s Dan Kara.

It will only be a matter of time before shiny metal arms join hand-in-hand with the hard hats dotting construction sites across the world.